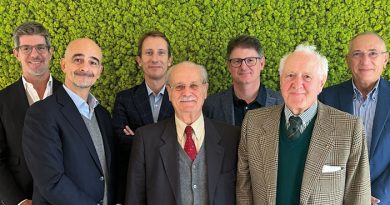

I cinquant’anni della Estral di Manerbio

Da piccola fabbrica di profilati estrusi a grande realtà industriale: il team dirigente del Gruppo Estral raccontano mezzo secolo di sviluppo

Tutto sul mondo della produzione di alluminio, estrusi, getti di fonderia e laminati, con aggiornamenti su tecnologie, macchine e prodotti

Da piccola fabbrica di profilati estrusi a grande realtà industriale: il team dirigente del Gruppo Estral raccontano mezzo secolo di sviluppo

La ceramica isolante preformata della serie ECOSIL, sviluppata da Foundry Ecocer, riduce la perdita di calore durante il trasporto e il contenimento dell’alluminio liquido nei processi di fusione

Il sistema Total Thermal Vision di Marposs verifica la corretta solidificazione del getto d’alluminio misurando la distribuzione della temperatura sulla superficie dello stampo

Mauro Durazzi, Direttore marketing e sviluppo commerciale di Kromoss è stato eletto all’unanimità alla presidenza di UNICMI per il biennio 2024-2025

Fives è specializzata nella fornitura di soluzioni innovative per la produzione di alluminio primario, come impianti ad alta capacità per anodi verdi, centri di trattamento dei gas e dei fumi e sistemi di controllo della combustione per i forni di cottura degli anodi

Lo smelter del Bahrain ha avviato un importante piano strategico di investimenti per spingere sulla decarbonizzazione e la produzione di alluminio green. Lo spiega Ali Al Bakari, CEO di Alba

La transizione energetica e la sfida della decarbonizzazione i temi caldi della 25a ed. di Arabal, ospitata a Riyad da Ma’aden a novembre 2023

Alla fiera di Norimberga i tre giorni di manifestazione hanno messo in mostra e le tecnologie, i processi e i prodotti più innovativi

Texpack® è specializzata nella produzione di sistemi di tenuta e prodotti per alte temperature, con una gamma di prodotti.

Mingtai AL è la prima azienda in Cina a testare l’alluminio da anodi inerti per prodotti commerciali.